I, like many others, enjoy the ramblings of Scott Hanselman. Recently, Scott posted a blog on how he got started in computers and programming and I thought I'd share my own story of getting started.

Domesday

It all began in the distant past (don't worry, the story isn't as long as it sounds) when I was at primary school (elementary school for those Americans reading). We were very fortunate in the UK during the 80s; the BBC was working hard to promote computer literacy. This culminated in a number of things, most notable (at least for this story) were the BBC Domesday Project and the BBC Micro.

The Domesday Project was a partnership between the BBC, Acorn Computers and various others to mark the 900th anniversary of the original Domesday Book, an 11th century census of England. It resulted in our school library having a laserdisc that gave us an unprecedented interactive view of the country.

The BBC Micro was the computing platform that formed a part of the Domesday Project and my formative programming experience thanks to the BBC's efforts to get one in every primary school in the UK.

We have lift-off!

It was a year or so after the Domesday Project had visited our school library. A BBC Micro sat conspicuously in my classroom day after day. I don't remember exactly how it started, but at some point I went from playing educational games on it to writing small programs in BASIC. I suspect it had a lot to do with a very inspirational teacher I had (Mr. Garbutt, I believe). He read fascinating books to us, he played guitar to us, he had us writing and remembering poetry and eventually, he had me writing software.

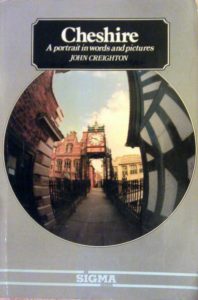

It was towards the end of my final year, shortly before my leap to high school, when I created my most elaborate program yet. It was a picture of a space shuttle complete with scaffold and a car with stickman owner for scale. It even had NASA written down the side (for someone who still struggled with some geometry at age 10, I am impressed with myself for rotating those letters). The program itself was more a feat of effort than it was of programming ingenuity; it was several hundred lines of MOVE and DRAW commands. However, that effort earned me a £10 book token and a printout of the drawing and the code used to create it. The printout has since been lost, but the book I purchased has journeyed with me and sits in my bookcase at home, inside it is taped the card that had contained the prize.

The Theory of Relativity

If it were not for the support and sacrifices of my family, that may well have been that. I would have left primary school and perhaps programming, behind. However, my parents recognized my interest and bought a home computer. It was a Tatung Einstein, a little known microcomputer and it was perfect for me to while away hours at home gaming and coding (now I come to think of it, this may be how I got my start with videogames too).

I wrote a whole host of programs for my Einstein including electronic versions of "choose your own adventure" books, an electronic Beatles album and a timetable manager for me and my classmates to use for who knows what. I even remember using the Einstein for our stall at a school business fair (I seem to recall it was some sort of murder mystery thing though I don't remember for sure).

Friend and Family

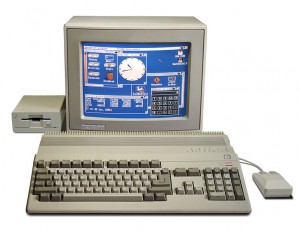

As my Tatung Einstein started to suffer from technical problems I set my sights on something grander; a Commodore Amiga 500. My parents sold our piano to afford this computer, much to the chagrin of my sister (and probably my piano teacher, although I'd already found my lack of talent by then). Meanwhile, at school I gained access to a 286 PC and an Apple Macintosh. The former was part of my science work and often included some lunchtime visits to Sid Meier's Civilisation with a very supportive science teacher, Dr. Stec; the latter helped me to write legible schoolwork for various classes (thanks, Mr. Simpson), assist in the publication of the school newspaper and learn about e-mail for the first time.

And The Rest Is History

By the time I finished high school, my career aspirations were set and I headed off to get a degree in Computer Systems Engineering leading to my job as a software engineer. Along the way, I've had the opportunity to work with some amazing people on some great projects in some diverse circumstances and I owe it all to the opportunities I was given by the BBC, my schools, my teachers and my family. I will always be grateful for their support and the sacrifices that were made so that I could follow my ambitions.